Automating

Construction.

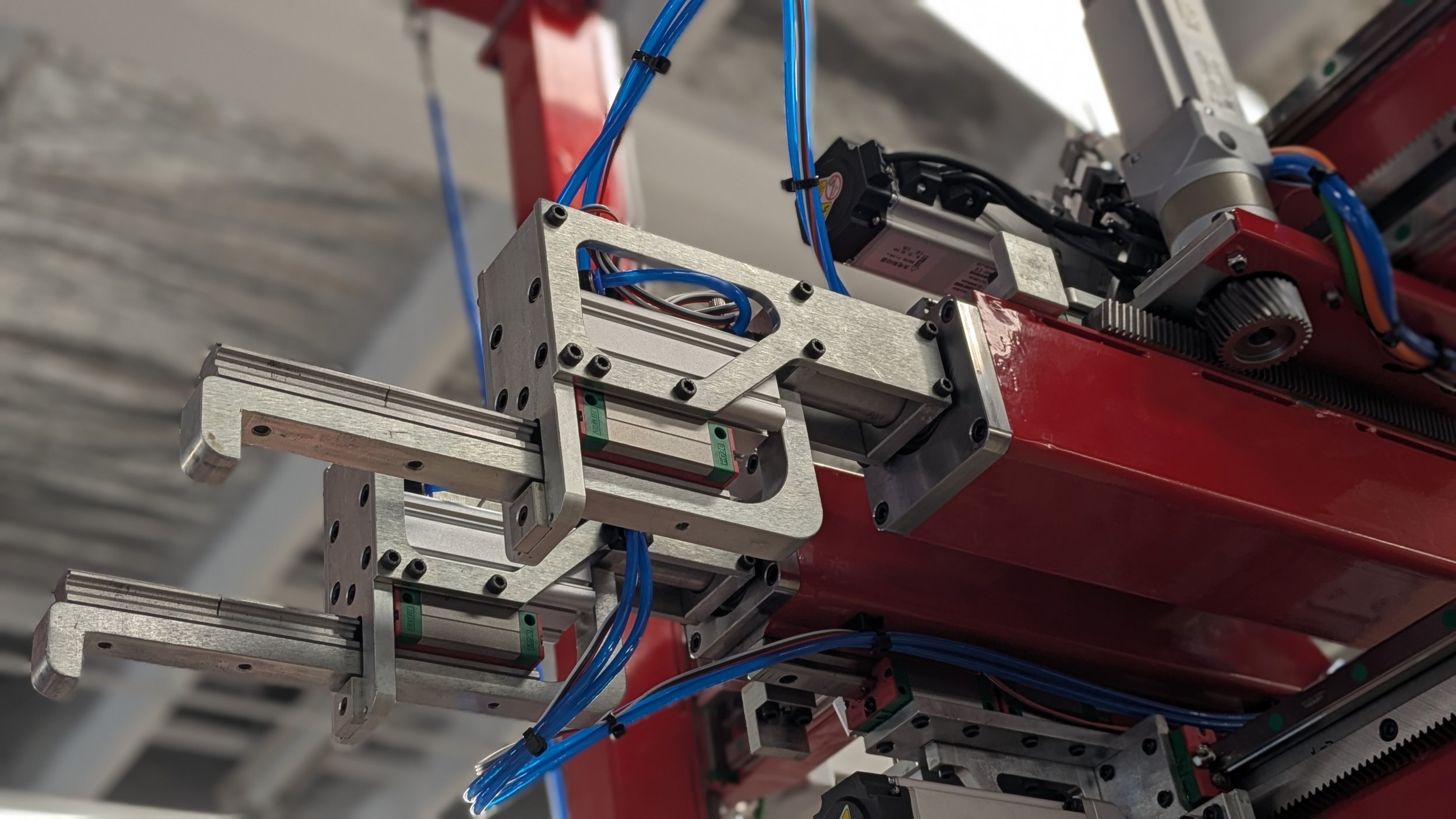

Our goal is to drive down the cost of housing construction while delivering a higher standard of building quality. At Stansted, we believe this can only be achieved through innovation. Our team bring together knowledge and experience from automated manufacturing systems and are now applying it to the construction industry. Our first focus is timber framing.

Build Better

Build Cheaper

Build Faster

Traditional timber frames are assembled by hand using sawn timber, which naturally contains imperfections such as bow, crook, twist, and knots. Because frame assembly relies heavily on manual labour, flaws and misalignments are common. Once the frames are stood on site, builders are often required to spend several days reworking, straightening, packing, and planing to fix these defects which costs building companies valuable time and money. Even when frames leave the factory straight, changes in moisture content cause the studs to warp and bow as they dry. Incorporating LVL into framing can eliminate the side effects of natural irregularities but its higher cost has limited its use to architectural homes where tight tolerances justify the expense.

90% of New Zealand homes are constructed with timber frames. Despite the rise of alternative methods such as steel framing, structural insulated panels, and even 3D-printed homes, timber framing remains the backbone of New Zealand housing because it’s proven, affordable, adaptable, and sustainable.

While the construction industry continues to struggle with declining productivity, other sectors like manufacturing have achieved remarkable efficiency gains through automation and robotics. Frame and truss plants have made steady, incremental improvements, but a true step change requires a redesign of the whole system.

At Stansted, we’re solving these long-standing issues by automating the entire framing process. Our system assembles frames from engineered LVL timber, a material known for its uniformity, strength, and stability. By combining precision robotics with high quality LVL members, we are completely removing the variability of manual assembly so that every component is cut, positioned, and fixed to sub-millimetre accuracy.

The result is a frame that arrives on site perfectly straight, square, and ready to stand, eliminating costly rework and saving builders days of labour. Stansted’s technology delivers architectural-grade accuracy at standard-build cost.

Launching Spring 2026

Expression of Interest

If you’re a builder or developer interested in partnering, early access, or learning more about our production capabilities, please reach out using the form below.